Bore Gages

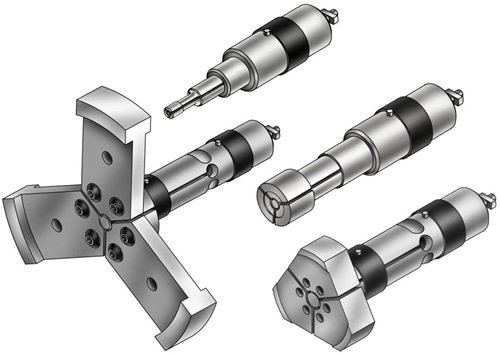

2 - POINT CONTACT GAGING

2 - POINT CONTACT GAGING

- Variable Bore Gage

- 2-Point Contact, directly opposite Ideal for detecting out-of-roundness

- Permits checking for ovality, taper, barrel shape, hourglass or bell mouth

- Dedicated to one size for production purposes, no errors in set-up

- Comparative system, set to master

- Self-centralizing and self-aligning

- Built-in back taper assures contact at front tips

- Capable of measuring to extreme bottom of bore

- Contact is under constant spring load

- Measuring is independent of differing operator skills

- Available for .090" to 15.9999" (2.286MM to 406.397MM) diameter holes

- Ranges from ±.003" / ±.075MM to / ±.030" / ±.750MM

- Contacts hardened to 60-62Rockwell C

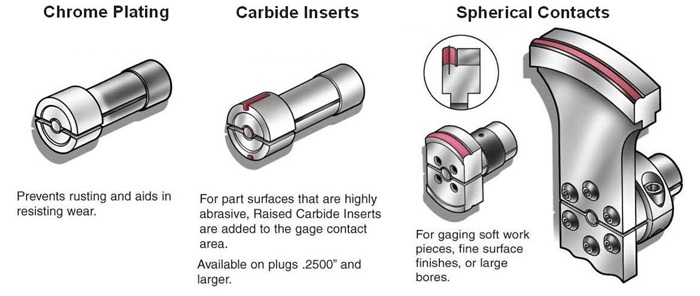

- Can be Chrome Plated or fit with Carbide Inserts to extend wear factor

- Self-compensating for wear

- Usable as a totally mechanical gage or in an electronic set-up

- Simple, accurate, time proven design

- Easily disassembled for quick change over and cleaning

- English or Metric

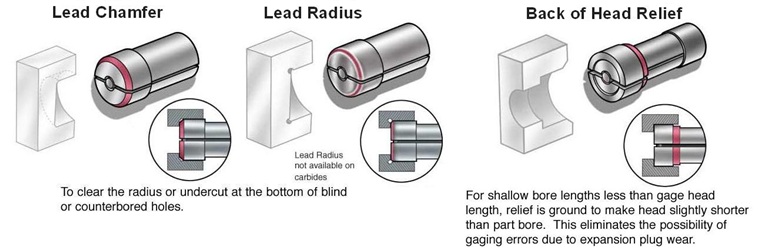

Expansion Plug options are available to increase the usefulness and effectiveness of the expansion plugs. Contact our engineering department for advice concerning a specific gaging application you must resolve.

NOTE: GAGE OPTIONS COULD AFFECT STANDARD GAGE SPECIFICATIONS/DIMENSIONS

* Click on images below for larger view.

(provides average measurements)

Ideal for checking tri-lobed bores, interrupted I.D.’s, or thin walled parts.

Three-Segment design (available for .1700” and above diameters) produces movement in three planes, and maintains true 120° contact through entire measuring range.

- Permits checking for taper, barrel shape, hourglass or bell mouth

- Dedicated to one size for production purposes, no errors in set-up

- Comparative system, set to master

- Self -centralizing and self -aligning

- Built-in back taper assures contact at front tips

- Capable of measuring to extreme bottom of bore

- Contact is under constant spring load

- Measuring is independent of differing operator skills

- English or Metric

- Ranges from ±.003” / ±.075MM to ±.018” / ±.450MM

- Contacts hardened to 60-62 Rockwell C

- Can be Chrome Plated or fit with Carbide Inserts to extend wear factor

- Self - compensating for wear

- Usable as a totally mechanical gage or in an electronic set-up

- Suitable for use at the machine or in an inspection environment

- Easily disassembled for quick change over and cleaning

Expansion Plug options are available to increase the usefulness and effectiveness of the expansion plugs. Contact our engineering department for advice concerning a specific gaging application you must resolve.

Gage Options

NOTE: GAGE OPTIONS COULD AFFECT STANDARD GAGE SPECIFICATIONS / DIMENSIONS.

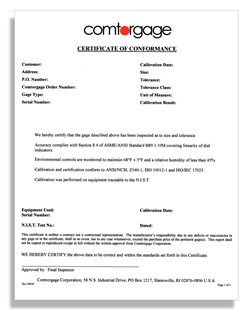

Certification

Conforms to Comtorgage specifications.

(Expansion Plug / Plug Checker )

* Click on image above for larger view.

Calibrations performed on equipment traceable to N.I.S.T.

Measurement and method of recording conforms ISO / IEC 17025.

Testing Equipment for Expansion Plugs