Customized Gages

COMTOR SPLINE GAGES

- Dedicated to one size, thereby minimizing errors in set-up

- Internal or External Splines and Gears

- Even or Odd number of teeth

- Inch or Metric

- Ranges from ±.003" / ±.075MM to ±.030" / ±.750MM, based on size

- Simple, accurate, repeatable, time proven design

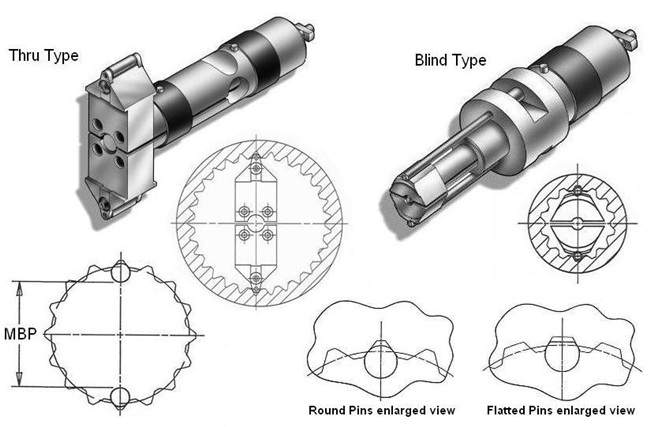

Internal Spline-Measurement Between Pins (Pitch Diameter)

Gages to check the pitch diameter of internal splines are based on a measurement between gage pins. The Comtor Spline Gage incorporates the time proven method of using gage pins to contact at the pitch line while eliminating the cumbersome task of holding gage pins in place while measuring with a micrometer or caliper. The gage pins "float" allowing them to contact on the pitch line and settle between teeth.

- Gage pins serve as an aligning and squaring feature while also providing the advantages of a ball contact

- Permits checking taper and out-of-roundness

- Available for applications that require round or "flatted" pins

- Blind Type allows checking to the bottom of the spline

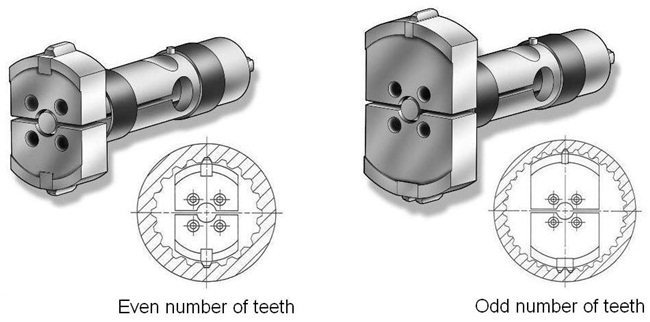

Internal Spline-Major Diameter

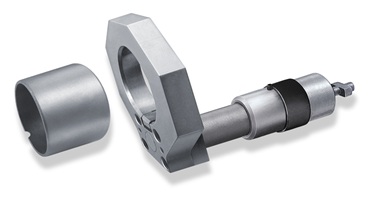

Gages to check the major diameter of internal splines incorporate Protruding Inserts to settle between spline teeth. Two contact points are offered to check splines with an even number of teeth. Three contact points are offered to check splines with an odd number of teeth. Inserts are either Form Ground or Straight Sided based on spline configuration.

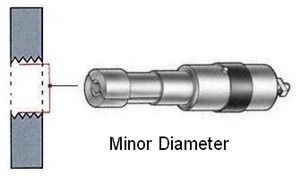

Internal Spline-Minor Diameter

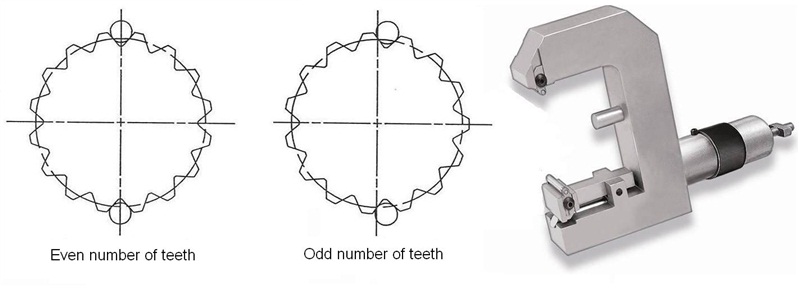

External Spline-Measurement Over Pins (Pitch Diameter)

For both even and odd number of teeth, a locator aligns pins between teeth.

External Spline-Major Diameter

Comtorgage’s OD Blade Gage is commonly used to check the major diameter of an external spline.

External Spline-Minor Diameter

Form Ground Contacts settle between spline teeth

COMTOR BLADE GAGES

- Snap Ring Grooves, O-Ring Grooves, Seal Grooves, Recesses, Flexible Parts, Plastic Parts, Interrupted Grooves and Bores

- Dedicated to one size based on part configuration, thereby minimizing errors in set-up

- Fast, accurate measurements

- Blades are projected simultaneously

- Work piece is under constant spring load thereby minimizing operator influence on the measuring process

- Allows detection of out of round conditions

- Meets strict tolerances

- Internal or External

- Inch or Metric

- Ranges from ±.003" / ±.075MM to ±.040" / ±1.000MM

I.D. Blade Gages

- Design incorporates two or more blades, that retract into a housing, then when in gaging position, extend to contact the surface being measured.

- Gage is self centralizing by means of the housing, which is designed to pilot through an entry bore.

- Available with a Depth Stop to align the contacts with the area to be measured.

- Blades can be form ground to accommodate the groove configuration.

Double-Acting Blade Gage

- Applications are similar to the ID Blade gage

- Gage is self centralizing by means of the housing, which is designed to pilot through an entry bore

- Designed for deeper groove applications where additional retraction is required to access the groove

Blade Gage-Snap Ring Groove

- Designed to measure the "snap" groove of the plastic food container.

- Multiple blades allow maximum peripheral contact of the groove.

- Allows "rounding out" of the part without distorting.

- Insures proper size of groove which has direct influence on freshness of food.

Blade Gage-Minor Internal Thread Diameter

Designed to measure the minor internal thread diameter, of flexible parts.

Designed to measure the minor internal thread diameter, of flexible parts. - Made to the specific minor diameter of the thread.

- Multiple blades allow maximum peripheral contact.

- Allows measurement without distortion or stretching of the part.

- Blades retract into a pilot housing that is slightly smaller than the thread minor diameter.

- Gage is self centralizing.

Blade Gage-Reform Bead

-

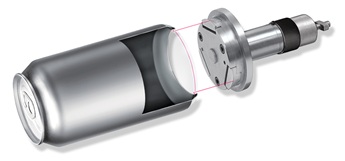

Designed to measure the reform bead (the round-bottomed internal groove diameter) on the underside of the aluminum can.

Designed to measure the reform bead (the round-bottomed internal groove diameter) on the underside of the aluminum can. - Three retracting blades positioned 120 degrees apart.

- Allows measurement without distortion of the thin aluminum can.

O.D. Blade Gage

-

Designed to measure external gears with even or odd numbered teeth or center hubs deep inside parts having limited access.

Designed to measure external gears with even or odd numbered teeth or center hubs deep inside parts having limited access. - Gage is self centralizing by means of the housing, which is designed to pilot over the feature being measured.

COMTOR THREAD GAGES

- Operates on the same principle as the Comtor Blade Gage

- Uses “three-point” floating contacts at pitch diameter comparable to the a three wire system

- Measures the pitch diameter independently of lead errors, flank angle errors, major diameter, minor diameter, root radius, truncation, etc

- Dedicated to one size based on part configuration, thereby minimizing errors in set-up

- Fast, accurate measurements

- Internal or External

- Inch or Metric

- Ranges from ±.003" / ±.075MM to ±.040" / ±1.000MM

Internal Thread Gages-Pitch Diameter

- Utilizes probes having carbide ball contacts, made to a diameter representing the “Best Wire Size”, to provide direct-reading capability.

- Probes are projected simultaneously.

- Pilots in the minor diameter for centralization.

Internal Thread-Minor Diameter

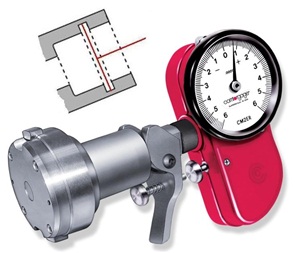

Comtorgage’s Standard Expansion Plug is commonly used to check the minor diameter of an internal thread.

External Thread Gages-Pitch Diameter

- Utilizes “Best Wire Size” high speed steel gage pins in a conventional over-the-wire measurement.

- The gage pins are allowed to float to compensate for lead error.

OTHER SPECIAL AND CUSTOMIZED COMTORGAGE APPLICATIONS

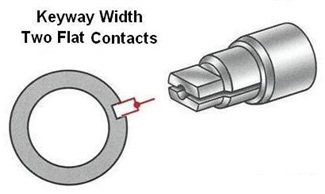

Flat Contacts, Hex, Square or Rectangular Gages

- Measure keyway widths; either internal or external.

- Able to check small, (down to .090”) widths of OD Grooves, ID and OD keyways.

-

Able to check taper in both directions.

Able to check taper in both directions. - To check non cylindrical shaped holes and slots.

- To check distance across planes.

- Gage squares itself in the part.

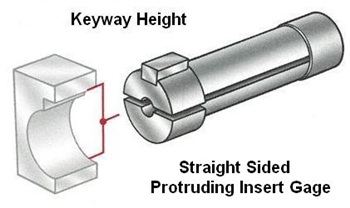

Straight-Sided Protruding Insert Gages

-

To measure the height of internal keyways from the opposing side of a bore by using a round gage head fit with a flatted protruding insert.

To measure the height of internal keyways from the opposing side of a bore by using a round gage head fit with a flatted protruding insert.

Diamond-Shaped Gages

(not pictured)

- Measures abnormally out-of-round conditions in a bore.

Dovetail Gages

- For checking dovetail shaped slides and tapered slots.

- Gage features radial contacts to assimilate gage pins when checking a “measurement between two pins” in a dovetail slot.

Tapered Bores

Tapered bores are checked by the use of two Standard Expansion Plugs, fit with Fixed Stops to check at different depths in the bore.

Tip Overhang Gages

- For checking I.D.’s where you have to clear a center hub, or center protrusion.

- Also, to check the I.D. inside of a trepanned groove.

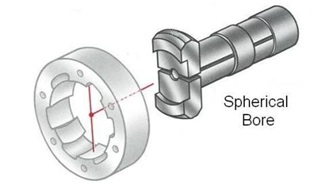

Spherical Gages

- Spherical Bores (bearing races, etc.) can be measured with our gage head that is spherically ground but still presents a 2-point contact.

Comtor Bridge Gages

- To check the distance across a specific length including groove widths and locations.

- Groove Locating and Groove Width gages are designed to seat against the bore I.D. during the measuring process.

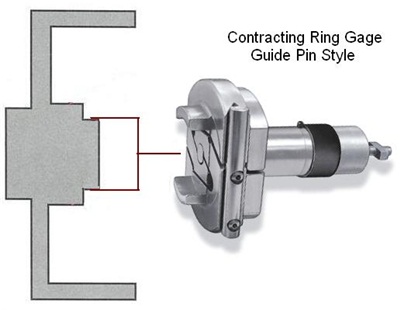

Comtor Contracting Ring Gages

- To check hub-type and “hidden” O.D’s. where conventional snap gages can’t be used.

- Can engage very short pilot diameters

- Can be designed with overhanging tips for checking trepanned grooves

- Reads out of round condition of part

- Allows detection of taper

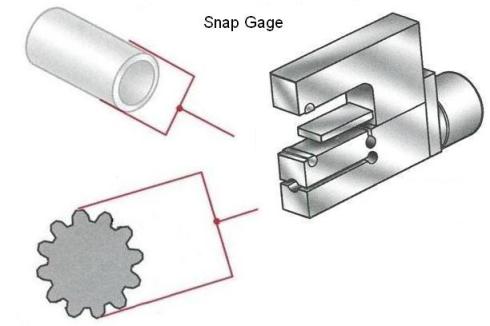

OD SNAP GAGES

- To check Shaft O.D.s, Shoulder O.D.s, Hub O.D.s, O.D. Groove Diameters

- Checks outside diameters of shafts quickly by way of a locator which aligns the gage contacts with the center shaft.

Send us your print and let us design a solution to your gaging problem.