Setting Masters

REFERENCE RINGS

Reference Rings are made of carefully selected steel that is heat treated for correct hardness, then stabilized and lapped to size. Unless otherwise specified, Reference Rings are sized to the mean bore dimension with a bilateral (split plus and minus) tolerance and class is determined by applying 10% of the total part gaging tolerance.

All Rings are carefully inspected for size and class with masters that are traceable to NIST. Calibrations conform to ISO/ IEC 17025 and tolerance specifications listed in ANSI B89.1.6

Environmental controls are monitored to maintain 68°F /-1°F with a relative humidity of less than 45%, assuring optimum measurement accuracy.

Proper gage inspection requires calibrating the gage at six separate points to determine size and geometry. The first three points measured are at the top, middle, and bottom of the x axis (left). The gage is then rotated 90 deg. so that the y axis is horizontal and the top, middle, and the bottom points of the y axis can be measured (right). Measurements for XXX class masters are made at the middle third only. These comparative measurements will reveal any deviation in millionths of an inch or hundredths of a micron from the mean.

Options for Reference Rings:

Special Marking (tool no., operation no., etc.)

Chrome Plating (Not available for rings under .1500”)

Certification of Size

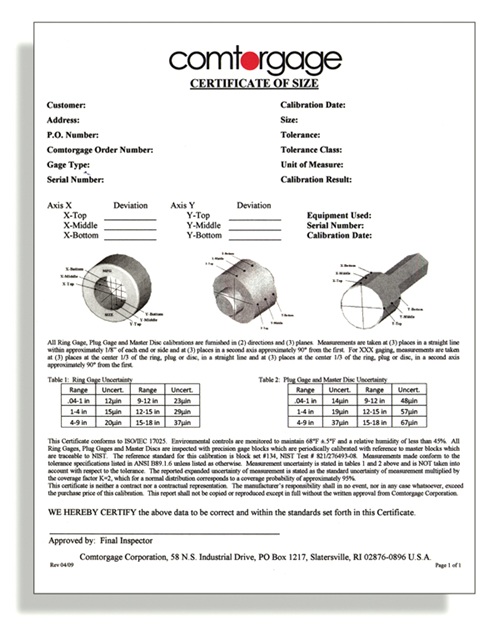

Certification

Certification of Size

Six measurements are recorded

Click on image above for larger view.

Gage Maker's Tolerances Chart

Master Blocks

Comtorgage offers custom designed Master Blocks to assimilate the measured "part characteristic" when standard masters are not suitable. Calibrations are directly traceable to NIST. Optional Certifications are available.

U-Shaped Master Blocks for use with internal gages that measure distance between planes, groove widths, groove location, and depth applications, such as Flat Contact Gages and Bridge Gages.

Master Blocks for use with external gages that measure distance across planes or over gage pins, such as Bridge Gages, Contracting Type Gages and Snap Spline Gages.

Master Blocks for use with external gages that measure distance across planes or over gage pins, such as Bridge Gages, Contracting Type Gages and Snap Spline Gages.

Taperlocks/Trilocks

Comtorgage Taperlocks and Trilocks are offered for use with external gages such as Contracting Ring Gages and O.D. Blade Gages.

Taperlock and Trilock tolerances are bilateral (split plus and minus) from mean size unless otherwise specified.

Calibrations are directly traceable to NIST. Optional Certifications are available.

Masters for Spline Gages

Comtor Internal Spline Pitch Diameter Gages are mastered using Sector Type Form Ring Masters or Cylindrical Reference Rings.

Comtor External Spline Pitch Diameter Gages are mastered using Rectangular Master Blocks.

Calibrations are directly traceable to NIST. Optional Certifications are available.

Masters for Thread Gages

Comtor Internal Thread Gages for checking pitch diameters are mastered using Solid Thread Ring Masters.

Solid Set Master features:

- Assimilates part condition

- Round and usable in any position, no restriction of mastering

- Rugged, Precise, and Stable, eliminating the need for resetting

Comtor Snap Thread Gages for checking pitch diameters are mastered using Externally Threaded Masters.

Calibrations are directly traceable to NIST. Optional Certifications are avai